The BGauss Scooter Project: A Journey of Innovation and Excellence

- 3D Magic

- Aug 30, 2024

- 5 min read

At 3D Magic, we love pushing the boundaries of automotive design and manufacturing. One of our coolest projects was developing the BGauss scooter. This project tested our skills and showed what we're capable of. Let's dive into the story behind this awesome project!

Taking on the Challenge

Project Name: BGauss D15

When BGauss approached us, they had a clear vision but faced significant hurdles. They wanted a sleek, customer-friendly electric scooter with unique features and a reasonable development cost. They were dealing with high costs from other engineering firms, especially for prototyping and pre-series production. This is where we stepped in.

Setting Our Goals

Main Objectives:

- Design, Engineering development, prototype and pre-series production of BGauss Scooter.

Challenges:

- High development costs.

- High prototyping and pre-series production costs.

- Significant initial capital investment for production tools.

We knew we had to deliver a solution that was innovative and cost-effective. Our work included everything from styling and rendering to engineering, testing, validation, and low-volume tooling and part production.

Crafting Solutions

Ideation & Sketching:

Initial Sketches:

Our journey began with the soul of a deer, embodying agility, grace, and strength. Inspired by this majestic animal, our designers sketched the initial concepts for our two-wheeler, capturing the essence of the deer’s elegance and agility.

Ideation:

These sketches laid the groundwork for our vision, blending aesthetics with practicality to create a vehicle that stands out in both form and function.

Final CAS Model and 3D Renders

Final CAS Model:

This model serves as the blueprint for our innovative two-wheeler, combining form and function seamlessly.

3D Renders:

Utilizing cutting-edge rendering techniques, we created stunning 3D renders that bring our two-wheeler to life.

Chassis Design and Engineering

Our team focused on creating a chassis that is both lightweight and durable. This involved precise engineering to ensure the scooter could handle various road conditions while providing a smooth ride.

Sheet Metal and Plastic Parts

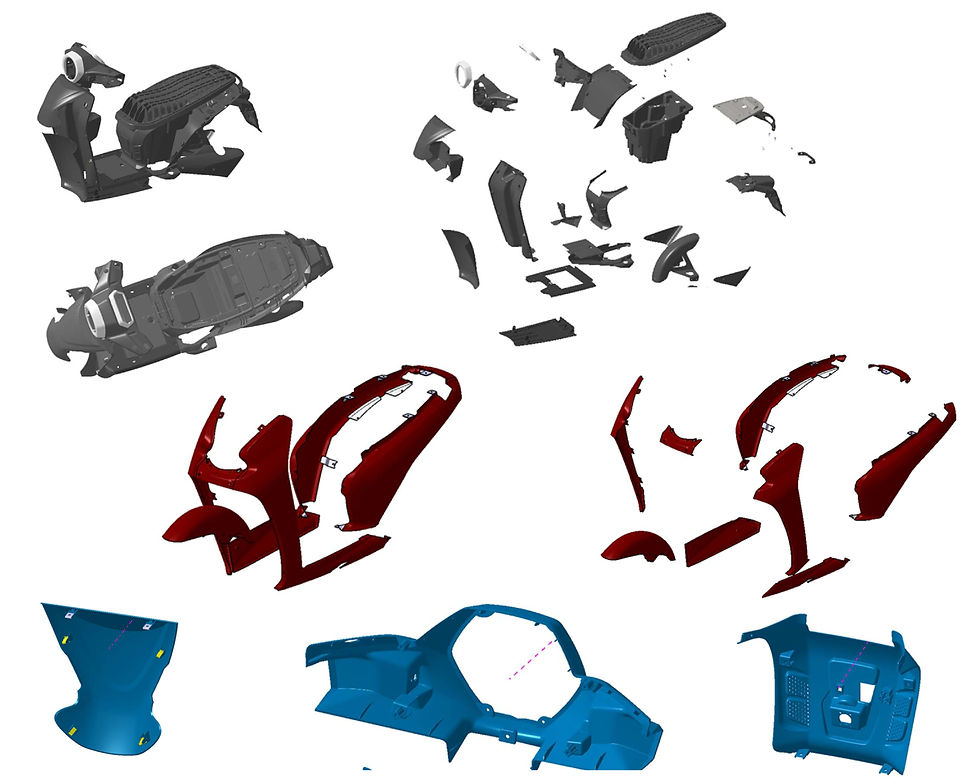

Sheet Metal Panel Engineering:

Our engineering team employed advanced techniques to design sheet metal panels that are both lightweight and robust. These panels are meticulously crafted to ensure durability and precision in every component.

Plastic Parts Engineering:

The plastic parts are engineered with a focus on reducing weight while maintaining strength and flexibility. Advanced molding technologies were used to create intricate and reliable components.

Innovative Approaches

One of our key innovations was using low-volume tooling for sheet metal components. This approach drastically reduced initial investment costs and allowed us to move quickly through the development phases. Additionally, we integrated several unique selling points (USPs) into the scooter's design, such as:

- Removable Batteries: The scooter was equipped with removable batteries, making it convenient for users to charge and replace them as needed.

- Perfect Ergonomics: Designed with the rider’s comfort in mind, the scooter offered an ergonomic riding position.

- Luggage Space: Ample storage space was provided, including a dedicated charging point for a mobile holder near the footrest.

The Manufacturing Journey

Manufacturing and Assembly

Tooling Feasibility:

Our Design team collaborated with in house industry experts to design tooling that maximizes production efficiency and minimizes costs. Precision tooling ensures each part is manufactured to exact specifications, maintaining high quality and consistency.

Prototype Development and Testing

Prototype Stages:

We developed several prototypes, each undergoing rigorous testing and refinement. This iterative process ensured that the final product met all performance and quality standards.

Final Prototyping Assembly

In the final stages, we assembled the prototypes, paying close attention to detail and ensuring that every component fit perfectly. These prototypes were then subjected to comprehensive testing.

Quality Control

Quality was paramount. We used CAE for rigorous analysis, followed by on-road testing and customer feedback through test drives. This ensured that our final product met the highest standards.

Results and Reflections

Project Outcomes

We successfully delivered 20 prototype vehicles for testing, validation, and marketing. These prototypes paved the way for the production phase, where we supplied over 500 sets of body panels. Our client’s vision was brought to life within the stipulated timeline and budget.

Client Feedback

BGauss was thrilled with the results. They praised the quality, design, and the cost-effective approach we brought to the project. Their positive feedback was a testament to our hard work and dedication.

Impact and Benefits

The impact on BGauss’s business was substantial. Our rapid design and development methodologies saved them significantly in development costs and cut down their development time by more than a year. These savings allowed BGauss to bring their scooter to market faster and more affordably.

Sales Success:

The success of the BGauss scooter is reflected in its impressive sales figures for the year 2023-2024:

- April: 771 units

- May: 1,814 units

- June: 191 units

- July: 661 units

- August: 923 units

- September: 935 units

- October: 1,171 units

- November: 1,609 units

- December: 1,215 units

- January: 1,487 units

- February: 1,350 units

- March: 3,108 units

These figures highlight the market acceptance and growing popularity of the BGauss scooter, reinforcing the effectiveness of our development and production strategies.

Looking Ahead

The BGauss project was just the beginning. At 3D Magic, we’re always on the lookout for new challenges and opportunities to innovate. Our team is constantly working on groundbreaking projects that redefine what’s possible in the automotive industry.

Join Us on Our Journey

We believe in sharing our journey and experiences with our community. If you’re passionate about automotive design and development, we invite you to follow our blog for more case studies, insights, and behind-the-scenes looks at our projects. Here’s a sneak peek at some of the exciting things we’re working on:

1. Modular Vehicle Concepts: We’re developing common vehicles that can be used by different OEM’s to create their own unique models. This approach not only reduces manufacturing costs but also speeds up the time to market.

2. Advanced Electric Vehicle (EV) Technologies: Our team is exploring cutting-edge EV technologies to create more efficient, sustainable, and user-friendly electric vehicles.

3. Collaborative Projects: We’re partnering with leading automotive companies to bring innovative solutions to the market. Our collaborative projects aim to push the envelope and set new standards in the industry.

Your Feedback Matters

We love hearing from you! Whether you’re a client, partner, or automotive enthusiast, your feedback helps us improve and innovate. Have questions or comments about the BGauss project or any of our other initiatives? Drop us a line in the comments section below or reach out to us on social media.

A Heartfelt Thank You

We’d like to extend our heartfelt thanks to BGauss for trusting us with their vision and for their invaluable collaboration throughout the project. Their success is our success, and we’re honored to have played a part in bringing their innovative scooter to market.

Stay Connected

Don’t miss out on the latest updates from 3D Magic. Follow us on social media and subscribe to our newsletter for exclusive content, industry insights, and more. Here’s where you can find us:

- LinkedIn: [https://www.linkedin.com/company/3d-magic/mycompany/]

- Instagram: [https://www.instagram.com/3d_magic_group/]

- Facebook: [https://www.facebook.com/profile.php?id=61557447813683]

Final Thoughts

The journey of designing and developing the BGauss scooter has been a remarkable experience for 3D Magic. It not only highlighted our technical prowess but also our commitment to delivering exceptional value to our clients. As we look to the future, we’re excited to continue pushing the boundaries of automotive design and manufacturing, always striving for excellence. Thank you for being part of our journey. Stay tuned for more exciting updates and stories from 3D Magic!

Feel free to share your thoughts and comments below. We’re excited to hear from you and engage in meaningful conversations about the future of automotive design and innovation. Until next time, let’s keep driving forward with 3D Magic!

Great Engineering contribution for a Greener world and Next Gen